I.8.

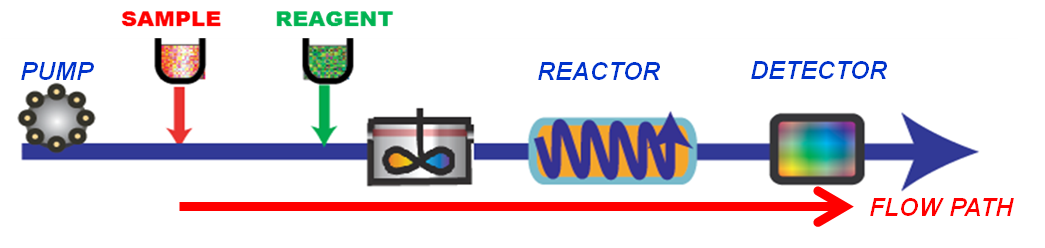

It is not justified to downscale a tool, because small items are appealing, or because one has access to micro fabrication facility. While micro fabrication proved to be immensely useful in electronics and other fields, its success in microfluidics has been limited, partly due to misidentification of the principal scaling parameters, and due to an ill defined purpose. Let us consider downscaling a simple flow system, that will meter and mix sample with a reagent , will allow the mixture to incubate for defined period of time, and will facilitate monitoring of a resulting product that will represent the content of the target species.

Microfluidics for Flow Analysis

If the purpose of miniaturization is to reduce reagent consumption, then the first parameters to be considered is the volume of the flow channel and the means by which the sample and reagent solution will be mixed. The design of lab on chip, also called microTAS, is based on assumption the radial mass transfer can only be accomplished by diffusion (Section 0.2.6.), which in turn dictates the maximum internal diameter of the flow channel to be 0.1mm or less. Thus at a flow rate of 1mm/second, the channel should be at least 5cm long, requiring a pressure of 15 bars to propel the solution forward at a constant, continuous flow rate. The sample and regent volumes will be in the range 0.5 to 1 microliter (microTAS). While fabrication of such a device is feasible, its use for performing assays faces several obstacles. The main issue is that the ratio of surface (of the conduit walls) to volume of the transported liquid, is far higher than in conventional flow systems, which has an unwanted effect of enhanced adsorption of species from processed samples. Another challenge is devising pumps, that would generate the low flow at a constant flow rate, and detectors suitable for monitoring target species in sub microliter volumes, moving trough 100 micron channel. While monitoring fluorescence or electrochemical responses is feasible, the sensitivity of UV-VIS spectrophotometry that is used in about 60% of all regent based assays, is severely restricted due to shortness of the light path.

Flow injection techniques use local turbulence to achieve mixing (Section 0.2.9), which in turn allows the use of large bore channels ( 0.8 mm.I.D).The volume of the flow path is reduced by keeping short enough to accommodate sample and reagent solutions, the combined volumes of which are below 100 microliters. This selection of volumes, and flow path dimensions facilitate processing real life samples, allows transporting fluids and suspensions at a wide range of flow rates, and accommodates almost all detection techniques. The downscaled version of SI performed in lab-on-valve platform (Chapter 2) has been widely used as documented in a recent comprehensive review (Miro and Hansen).

Small is beautiful.

E.F.Schumacher